INDIA Plastics processing

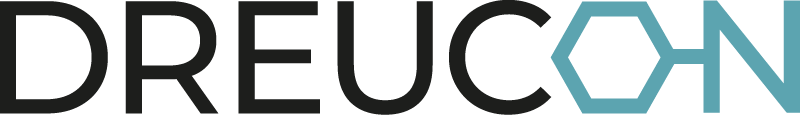

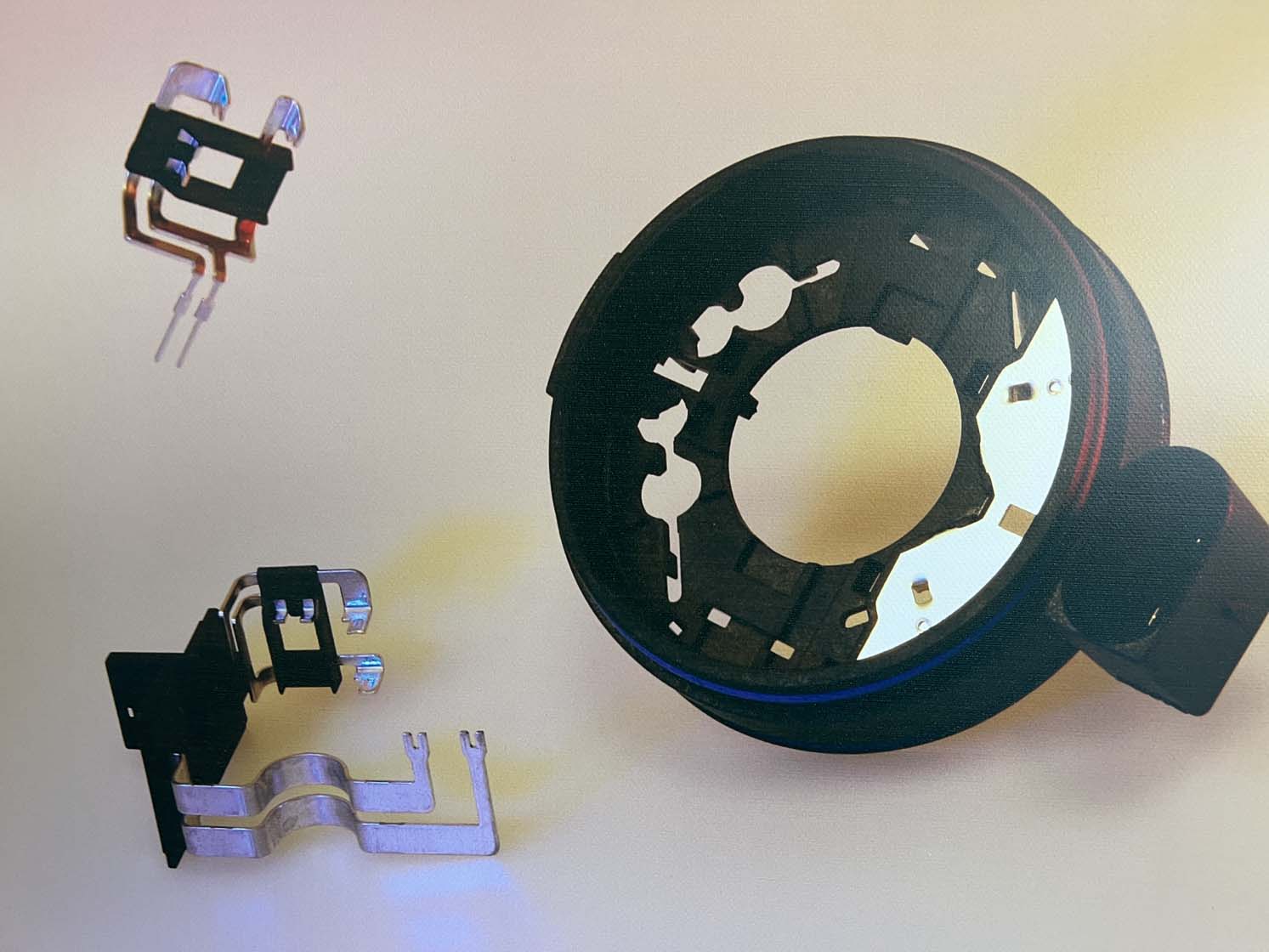

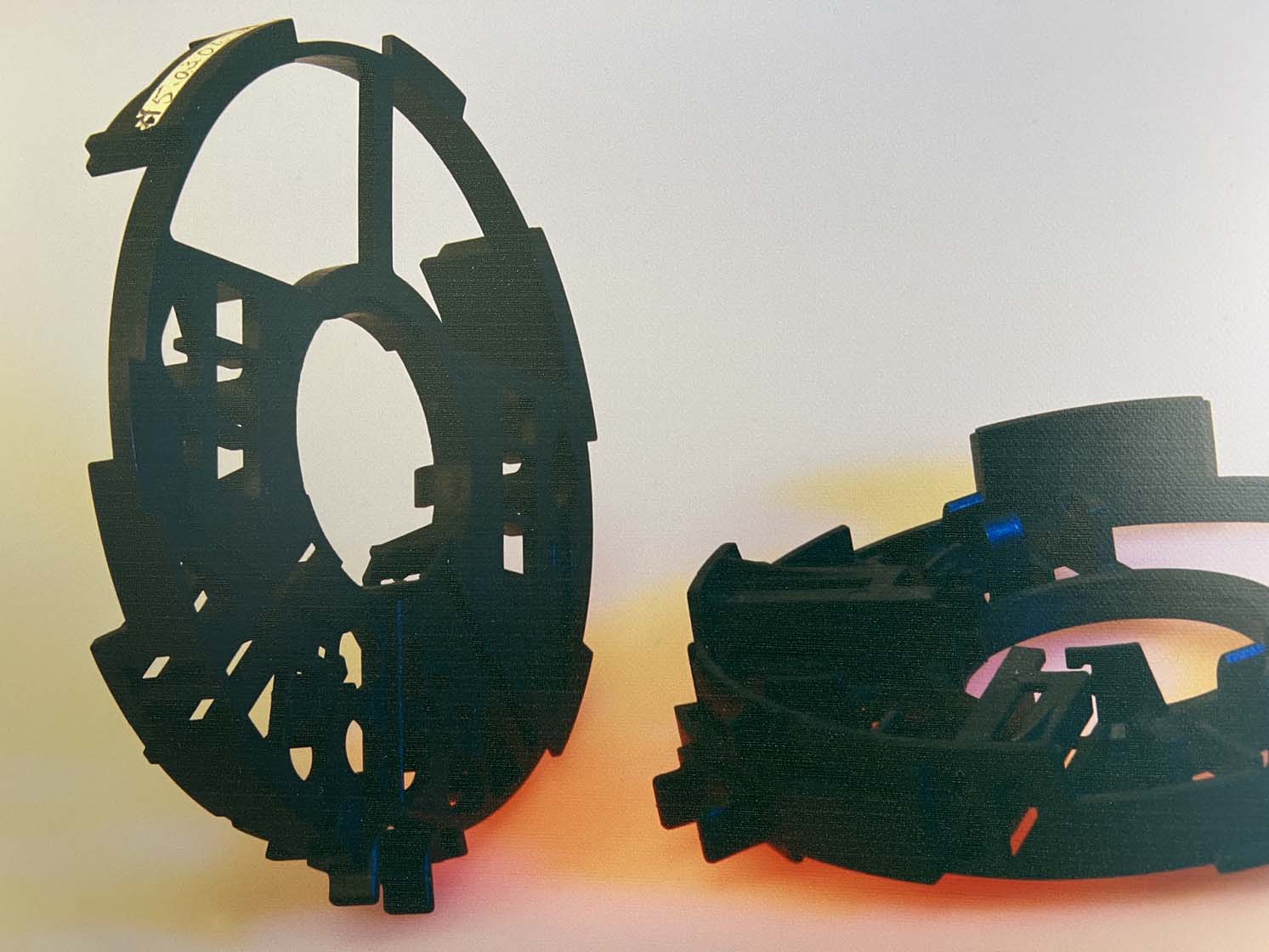

The company focuses on product design, prototyping (3D printing), mold making, quality-assured parts production, and the automation of production processes.

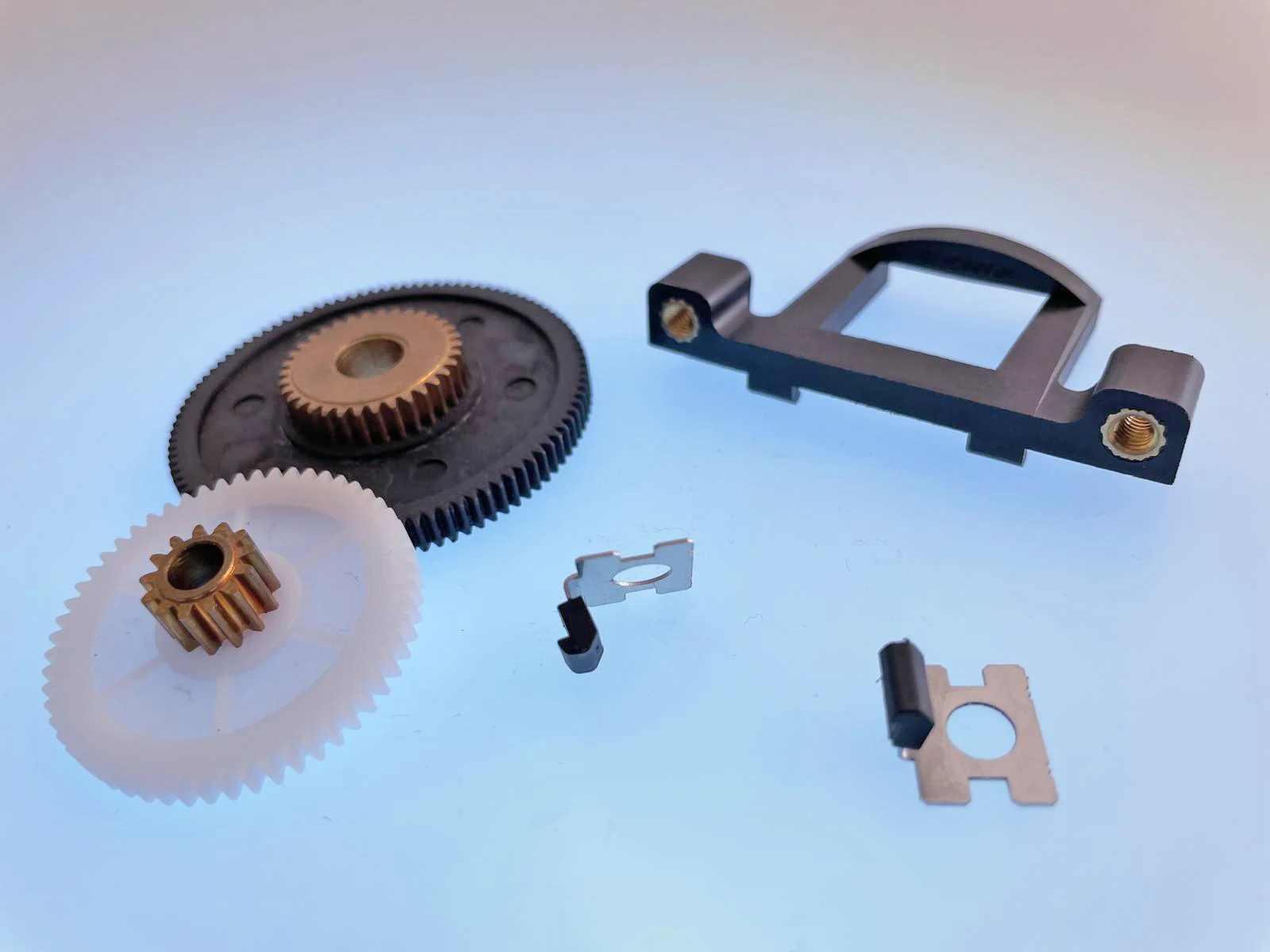

Highly automated injection molding production

INDIA Kunststofftechnik has a modern machine park that is consistently geared towards automation and efficiency. We use 38 hydraulic and fully electric injection molding machines from the renowned manufacturers Arburg and Engel.

- Clamping forces: 40 to 5,600 kN

- Part weights: up to 1.1 kg

- Automation: Robot removal with position-oriented placement

Printing of syringe bodies in a cleanroom environment

Digital production control in accordance with Industry 4.0

- Arburg host computer system

- Böhme & Weiß quality management system

- Wincarat ERP system

Tool and mold making

INDIA has a high-performance toolmaking department for:

- New construction of injection molding tools

- Maintenance and repair

- Construction of devices and customized automation solutions

With state-of-the-art processing machines and experienced specialists, toolmaking represents a key strength and foundation of the company’s technological capabilities.

PHOTO GALLERY

Address:

I.N.D.I.A. Kunststofftechnik GmbH

Nunsdorfer Ring 17

12277 Berlin

Contact

T +49 30 723700 – 0

F +49 30 723700 – 99

E info@india-berlin.com