OEHME Technische Kunststoffteile GmbH

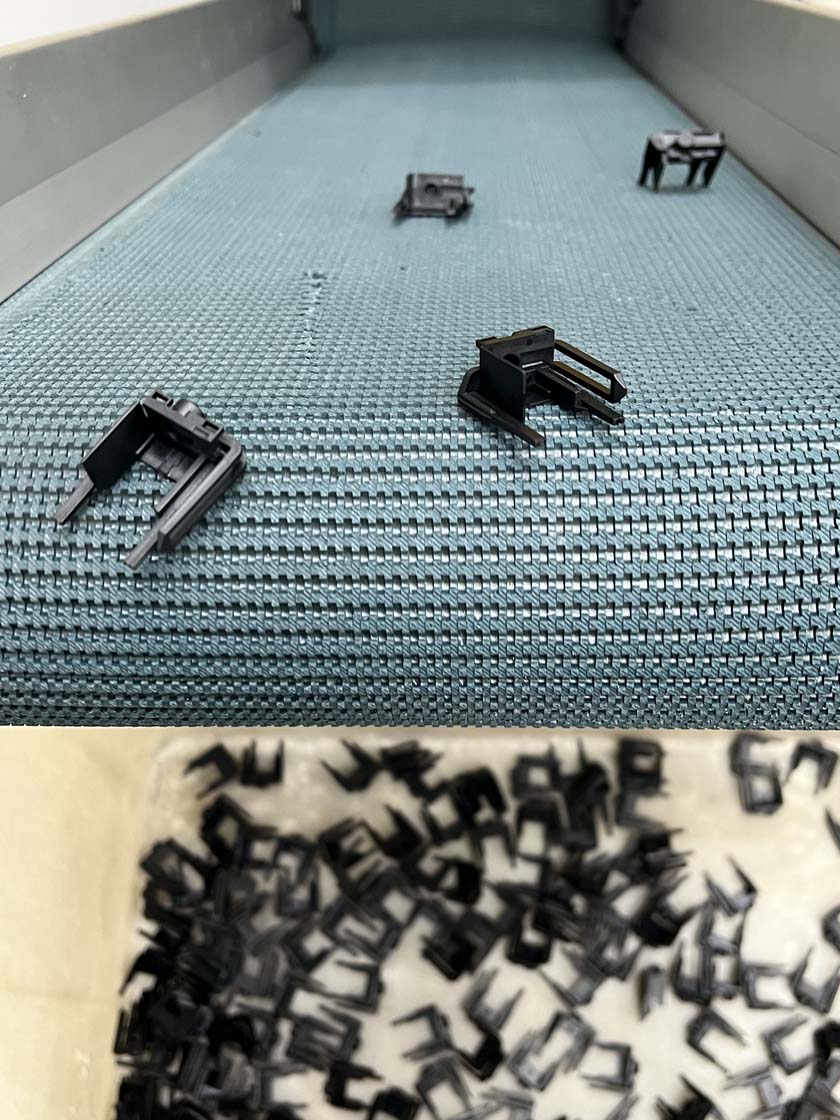

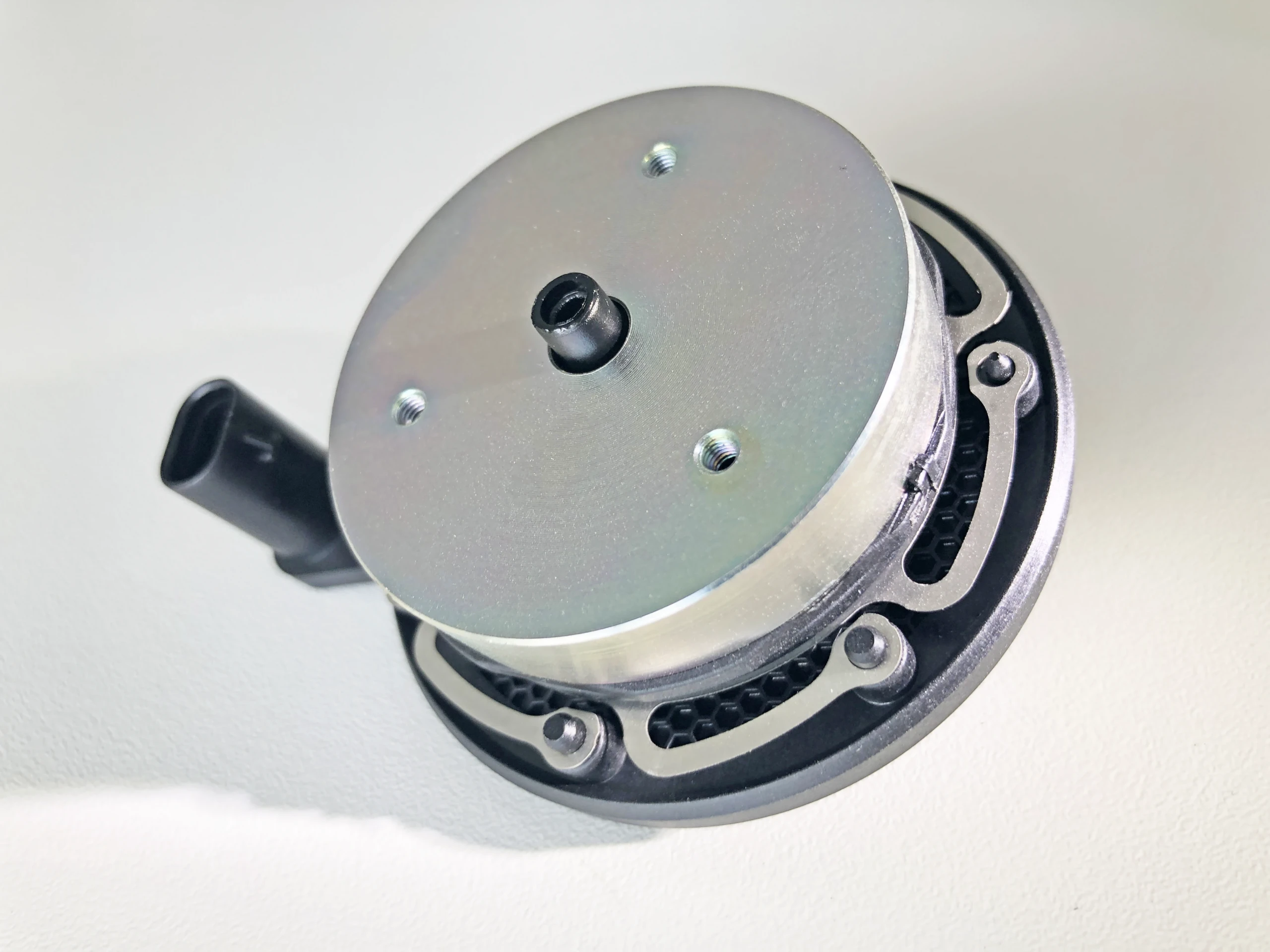

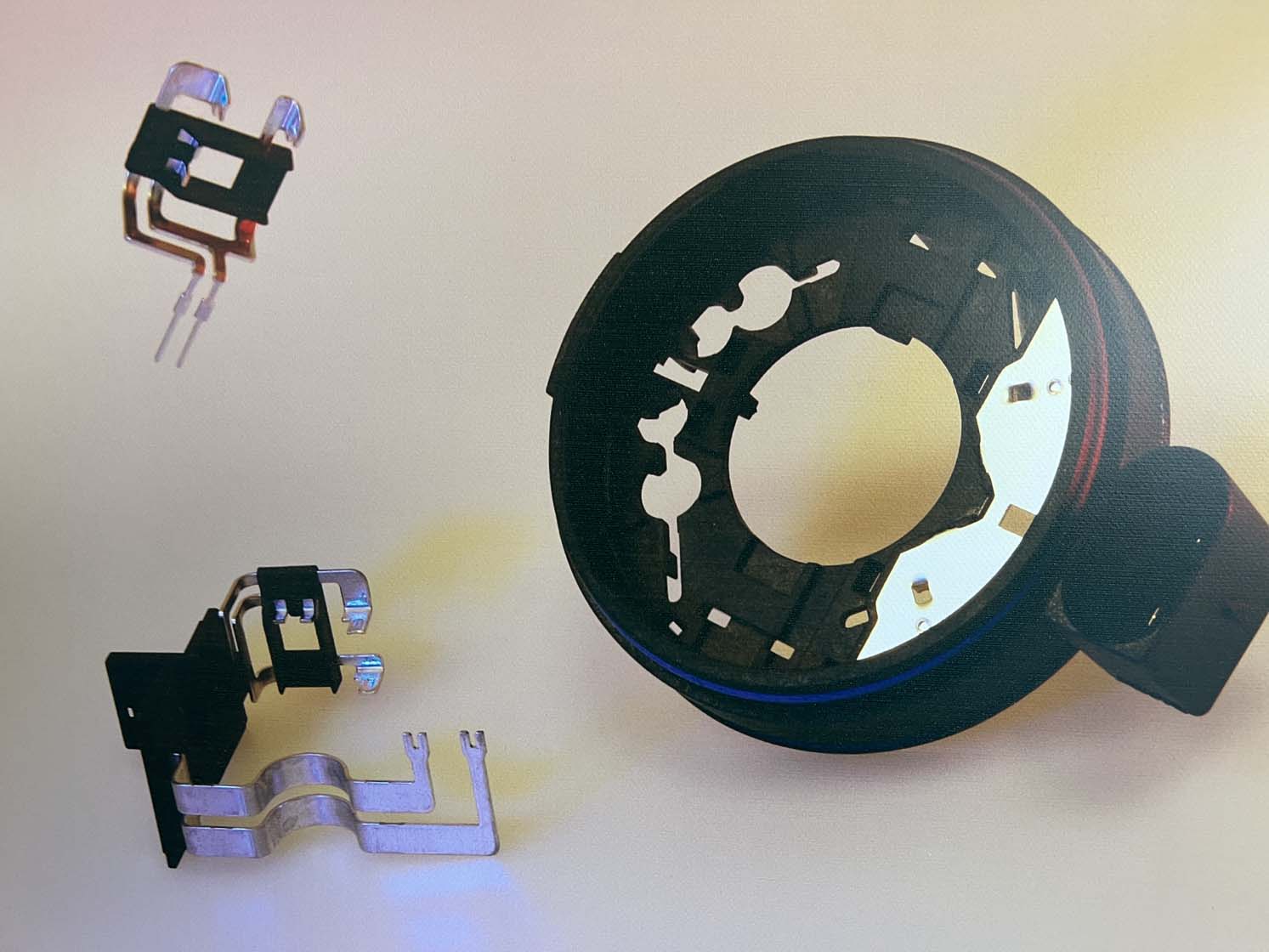

Expertise in overmolding metal parts

OEHME Technische Kunststoffteile GmbH specializes in overmolding metal components. These include:

- Pins for coil bodies

- Leaf springs

- Pots

- Cable

- Ball bearing

In addition, ultrasonic welding is offered as a modern joining technique for assemblies.

Quality assurance at the highest level

To ensure consistently high quality, an air-conditioned testing room is available directly in the production area. Keyence measuring systems provide support both in goods receipt and in production-accompanying tests.

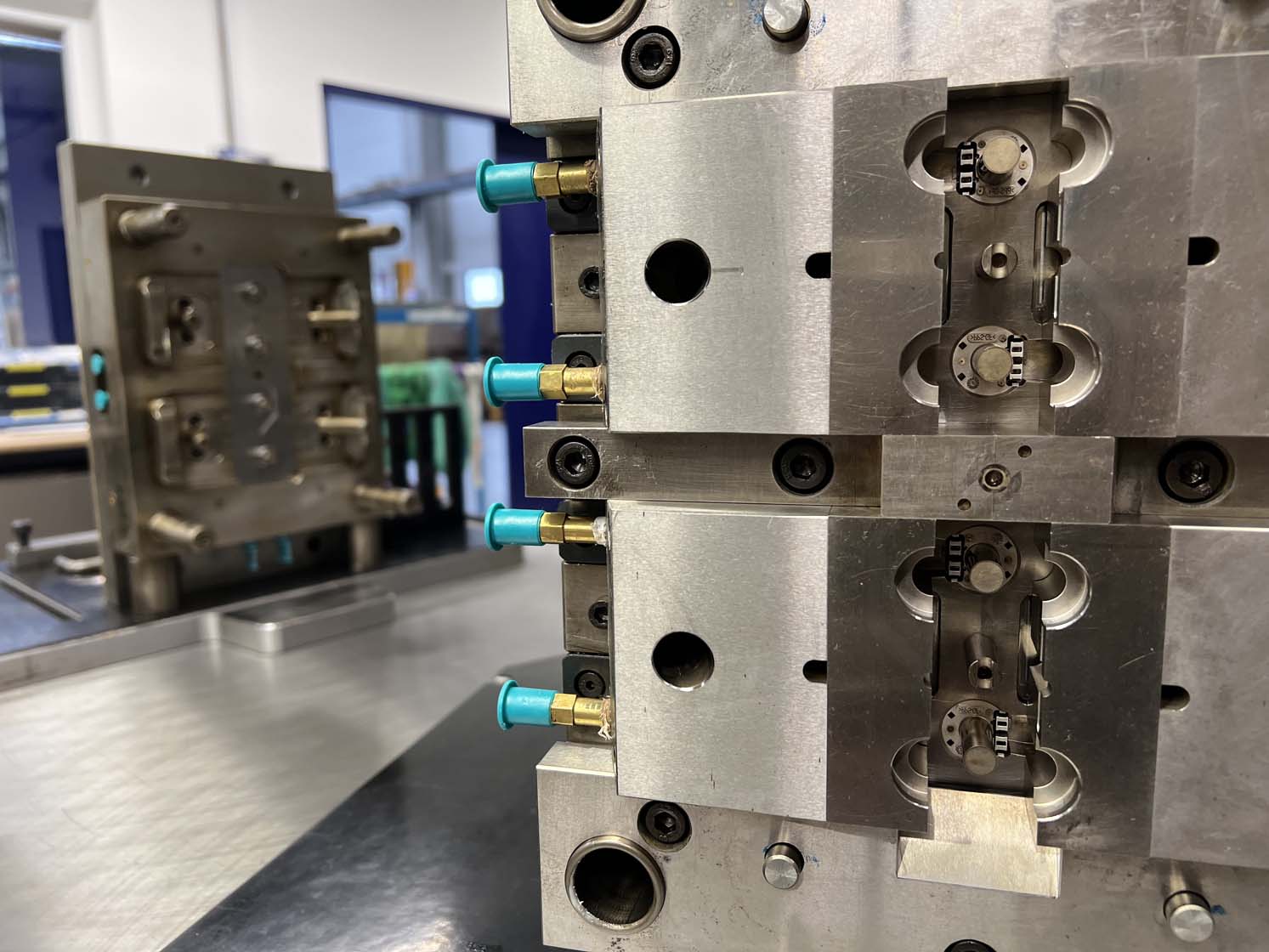

Toolmaking and maintenance

Our in-house toolmaking facility enables us to respond quickly to maintenance and minor repairs. The construction of new molds is centralized at our sister company INDIA. After each use, injection molding tools are thoroughly cleaned and repaired using ultrasound.

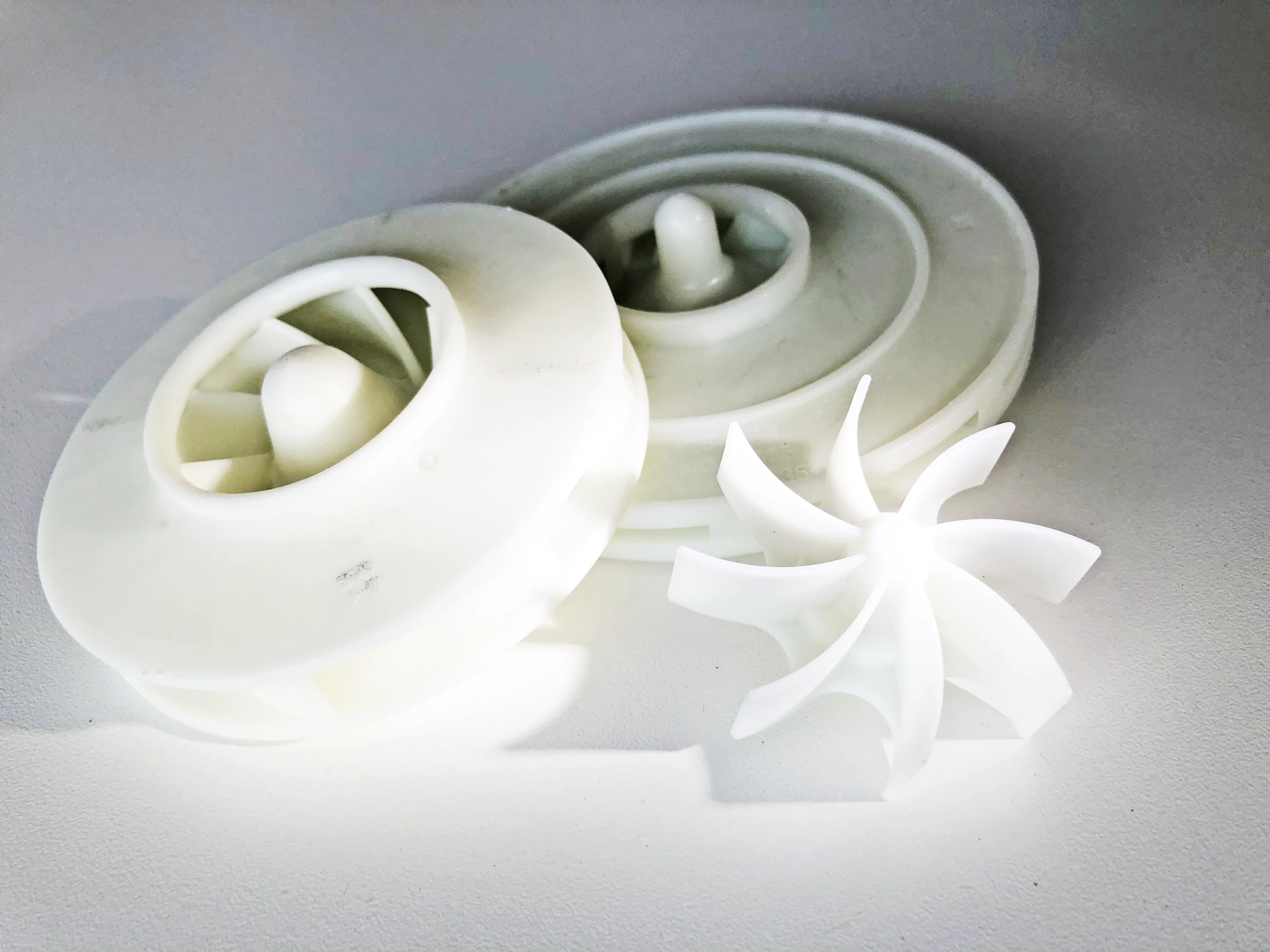

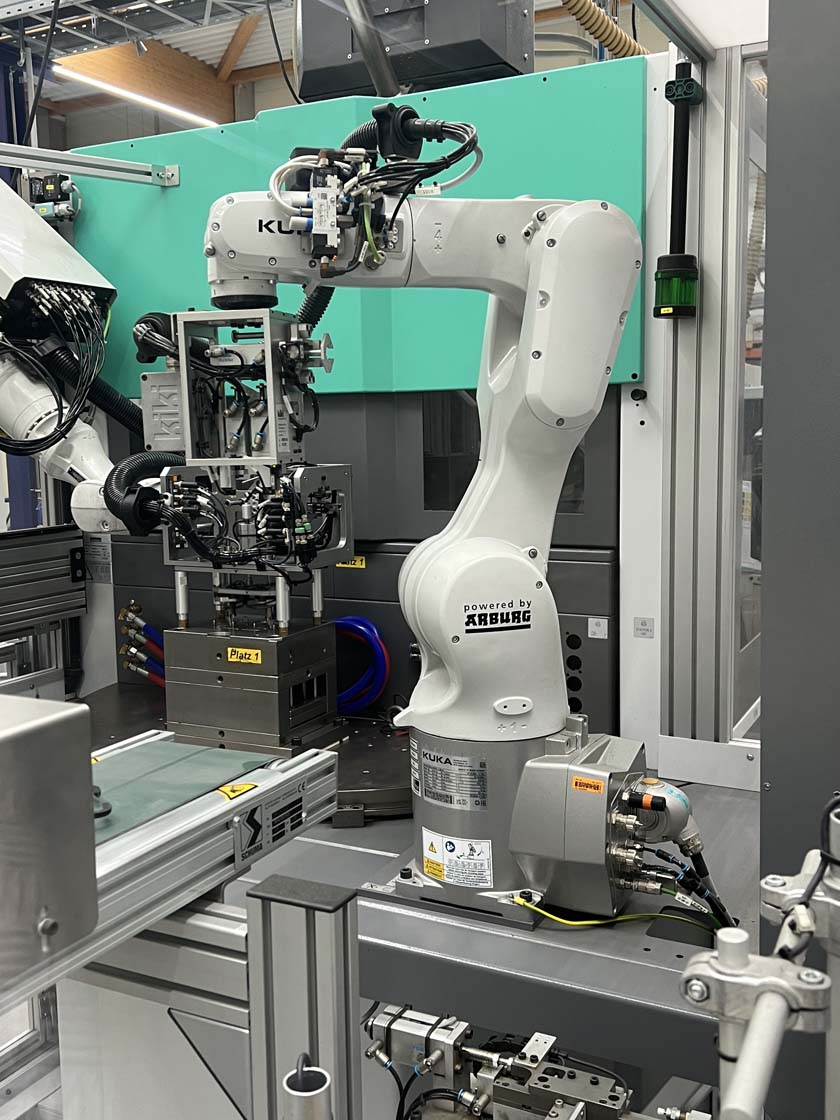

State-of-the-art machinery

The machinery consists exclusively of Arburg injection molding machines with the following performance characteristics:

Clamping forces: 150 kN to 2,200 kN

Shot weight: 1 g to 232 g (for PS, density = 1.0)

Vertical and horizontal injection (e.g., in the parting line)

Additional hydraulic connections (e.g., for core pulls, spindle units)

Freely programmable interfaces for individual customer requirements

- 28 injection molding machines, of which:

- 1 Two-component injection molding machine with pressure accumulator

- 7 round table machines:

- 1 × 275 V

- 2 × 375 V

- 4 × 1.200 T

- up to 1,000 kN clamping force

- Maximum turntable diameter: 1,200 mm

The rotary table machines are ideal for overmolding inserts and offer optimal cycle times for medium quantities that do not require full automation.

One of the large 1,200 T systems is fully automated and equipped with two 6-axis KUKA robots.

PHOTO GALLERY